Case Study: Siemens – Automated assembly line with fully automated material supply

The Customer:

With around 86,000 employees in Germany and over 300,000 worldwide, Siemens is one of Germany’s most important industrial companies.

Siemens is a leading technology company with a focus on the fields of industry, infrastructure, mobility and healthcare.

The project focused on the introduction of a new generation of high-performance industrial computers and control systems. A new, fully automated final assembly line had to be planned in an existing plant for the manufacture of this product. The material supply from the warehouse was also to be fully automated. A particular challenge was the tight space situation. During implementation, the customer attached great importance to a fully automated process that followed LEAN principles. The complex range of variants was to be mapped as flexibly as possible by logistics and assembly.

The Problem:

As part of the implementation of a new product series, the aim is to fully automate the final assembly of the product and the associated logistics processes.

The aim is to achieve a layout with a minimal footprint, high product variance and production in a one-piece flow. A high degree of innovation in the implementation is desired.

The Orise Solution

- Development of relevant staging concepts (single-variety/sequenced/carset).

- Allocation of load carriers, calculation of volume flows, buffer dimensioning and development of the information flow of the logistics concept.

- Clarification of requirements for the automated warehouse incl. dimensioning of storage locations and calculation of dynamics (consideration of Kanban and picking retrievals).

- Planning of an automated overhead transport system for space-efficient delivery to production.

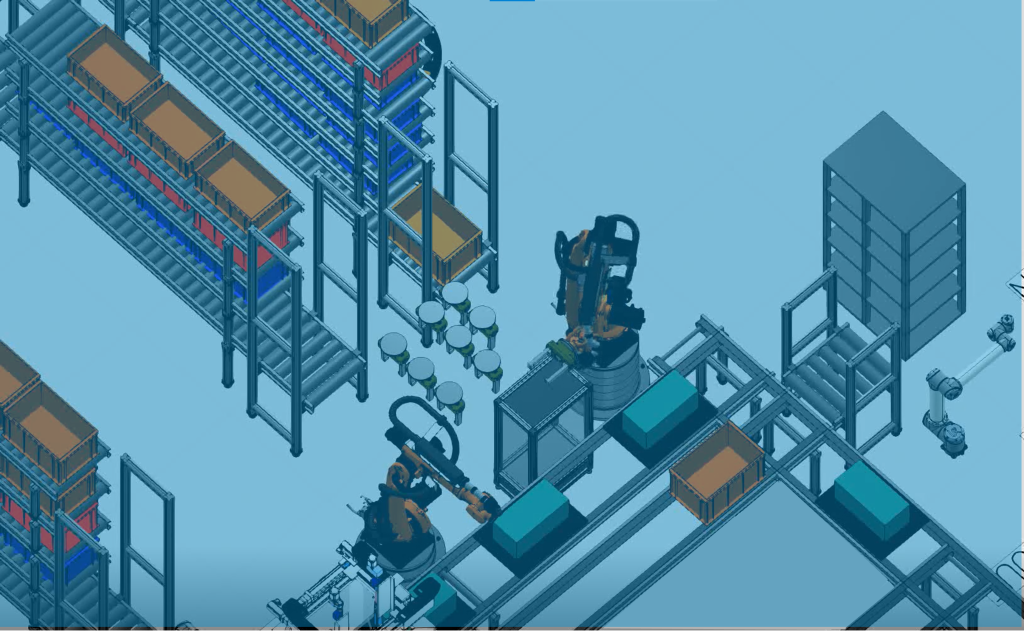

- Detailing (incl. 3D simulation), optimization & evaluation of the concepts with leading providers of innovative logistics systems for production supply.

- Design of a highly automated final assembly line with connection to the ceiling transport system. Mapping of the complexity in area-efficient cells with grippers and changing systems.

The Results:

Result is a detailed automation concept for the final assembly line including layout, 3D drawing, cycle time analyses, cost evaluation and footprint.

Evaluation of various logistics concepts (e.g. fully automated picking systems, car set formation, ceiling supply, AGV supply, buffer design), consideration of various alternatives and preparation of a decision paper for management.

“Together with the customer, we were able to develop a complete concept for assembly and material supply with innovative and individualized solutions in a highly productive project within 8 weeks. It was a particularly exciting challenge to ensure a one-piece flow among the high number of variants.”

- Maximilian Wolper, Project Lead, Orise