Asset Health Monitoring

Stop unexpected equipment failure before it disrupts production. Industrial AI designed for manufacturing excellence.

#matter

Why Asset Health Monitoring Matters

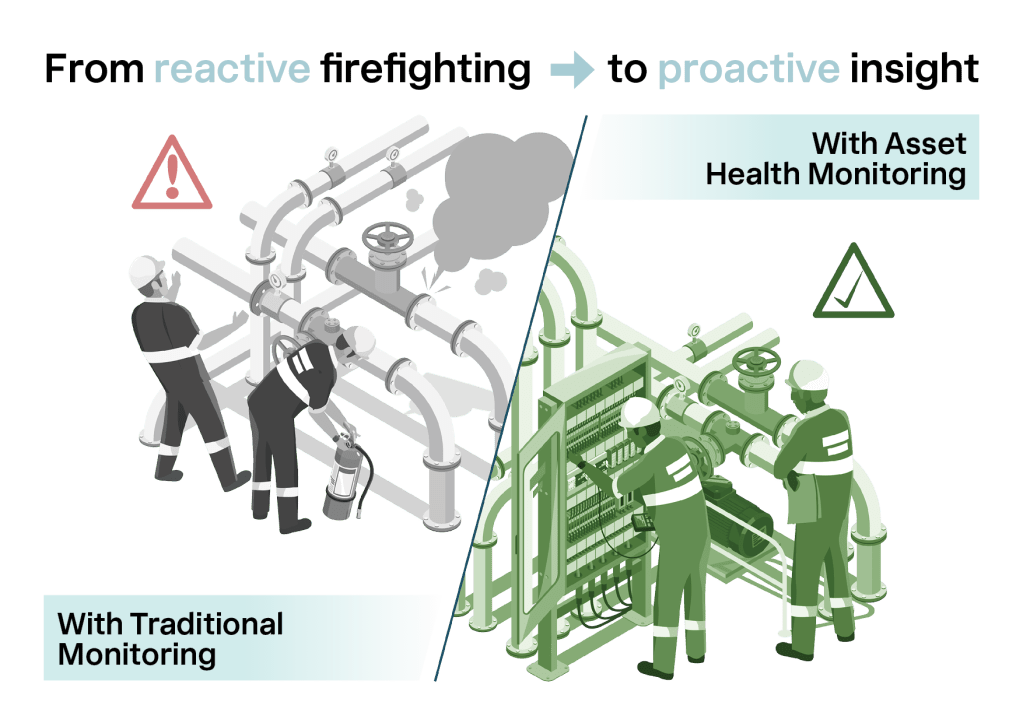

Manufacturing relies on continuous operation, but unexpected equipment failure creates costly disruptions across your entire production line. Asset Health Monitoring transforms maintenance from reactive firefighting to proactive prevention, addressing the core challenges that impact your bottom line:

- Unplanned Downtime – Production schedule disruptions and missed deadlines

- High Repair Costs – Emergency interventions and expedited spare parts

- Inefficient Maintenance – Unnecessary scheduled work that wastes resources

- Operational Uncertainty – Teams left guessing about true asset condition

Asset Health Monitoring eliminates these pain points by detecting equipment issues before they cause failures, ensuring smoother operations and predictable maintenance schedules.

#what

What is Asset Health Monitoring?

Asset Health Monitoring is an AI-powered software solution that identifies early warning signs of equipment failure using live sensor data before breakdowns disrupt production. The system comes with pre-engineered models for critical assets such as compressors, pumps, motors, controllers, and heat exchangers.

By combining advanced machine learning algorithms with human expertise, Asset Health Monitoring filters through vast amounts of data to highlight anomalies relevant to operational performance.

#works

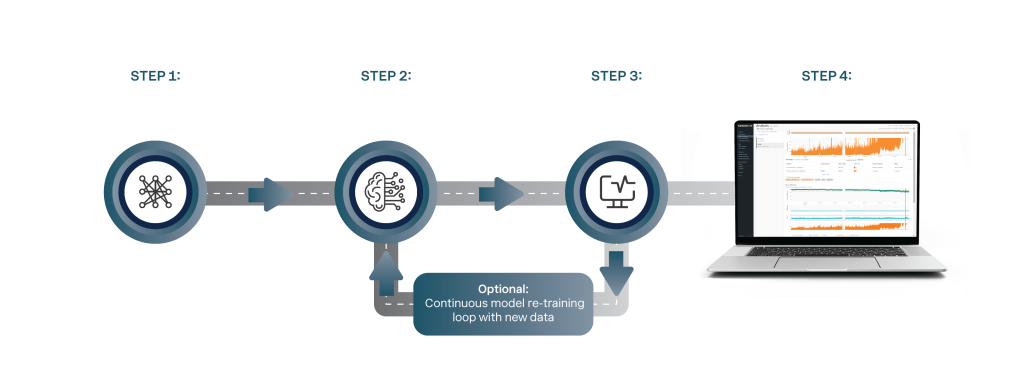

How Asset Health Monitoring Works:

- Connect – AI models integrate with your existing sensor data

- Learn – Systems train on historical performance patterns

- Monitor – 24/7 surveillance detects early warning signals

- Alert – Instant notifications keep teams ahead of potential issues

For specialized equipment, custom AI models deploy quickly and scale across similar assets, enabling rapid implementation without time-consuming data science projects.

#benefit

Key Benefits of Asset Health Monitoring

Prevent Unplanned Downtime

Detect equipment issues early and stop failures before they disrupt production schedules and delivery commitments.

Reduce Maintenance Costs

Transition from fixed schedules to intelligent, condition-based maintenance that addresses actual equipment needs.

Extend Asset Lifespan

Identify and resolve small issues before they escalate, reducing wear patterns and prolonging equipment service life.

Deploy Fast

Leverage pre-built models that require no manual formulas or specialized data science expertise for immediate implementation.

Scale Across All Machines

Monitor both standard and custom assets with reusable models that expand efficiently across similar equipment types.

Accurate Early Warnings

Receive precise alerts that enable quick response instead of time-consuming troubleshooting after problems occur.

Comprehensive Feature Set

Anomaly Detection

Identifies deviations from normal operating behavior using sensor data trends, detecting early warning signs of mechanical or process-related failures before escalation.

Intelligent Model Management

Central interface manages, trains, versions, and deploys monitoring models across asset types, supporting both pre-built and custom configurations.

Industrial Data Connectivity

Seamlessly connects to OPC UA, OSIsoft PI, relational databases, InfluxDB, Kafka, and CSV files for fast integration with existing OT and IT environments.

Customizable Alert Center

Delivers precise notifications via email, UI, or API with configuration options by machine, user role, or severity level to reduce noise and focus on critical events.

Real-Time Analysis Dashboard

Provides live overview of current alerts, machine trends, and anomaly history, helping engineers investigate issues and track resolution progress.

Multi-User Access & Organization

Enables structured access for operations, maintenance, and management teams with logical grouping of assets by lines, areas, or sites for scalable monitoring.

Built-in Data Processing

Includes ETL and preprocessing tools for importing, cleaning, and preparing sensor data, ensuring accurate anomaly detection without external processing requirements.

#faq

Frequently Asked Questions

How does Asset Health Monitoring integrate with existing systems?

Asset Health Monitoring connects directly to industrial data sources including OPC UA, OSIsoft PI, databases, and cloud platforms. Integration requires minimal setup and works alongside your current infrastructure without disrupting operations.

What types of equipment can be monitored?

The system monitors pumps, compressors, heat exchangers, motors, drives, and control systems. Pre-built models cover common assets, while custom models can be created for specialized equipment and reused across similar machines. Additionally, generic models can be applied for any issues with unclear boundaries.

How quickly can Asset Health Monitoring be deployed?

Implementation typically takes days to weeks, not months. Pre-engineered models eliminate lengthy setup processes, and the system integrates with existing data sources for immediate monitoring capabilities. After just a few clicks to set up, you’re good to go — no data science experience or customization required.

What industries benefit most from Asset Health Monitoring?

Pharmaceutical, biotech, chemical, energy, food, and beverage manufacturing industries see significant value from preventing unplanned downtime and optimizing maintenance schedules.Pharmaceutical, biotech, chemical, energy, food, and beverage manufacturing industries see significant value from preventing unplanned downtime and optimizing maintenance schedules.

How accurate are the early warning alerts?

The AI-powered system learns normal operating patterns for each asset, providing precise anomaly detection that reduces false alarms while ensuring genuine issues receive immediate attention. It integrates human expertise alongside the AI algorithms, tailoring the overall system to unique, industry-specific needs to dramatically reduce false alarms when compared to generic models.

Transform Your Maintenance Strategy Today

Stop waiting for equipment failures to disrupt your operations. Asset Health Monitoring provides the intelligent insights needed to maintain peak performance across your manufacturing processes.