Micro-Stop Detection

Detect unknown production slowdowns before they impact throughput with AI-powered real-time analysis.

Why Micro-Stop Detection Matters

Hidden micro-stops silently erode your production efficiency. These brief interruptions—lasting just milliseconds to seconds—rarely trigger alarms but accumulate into significant throughput losses. Traditional monitoring systems miss them entirely, leaving you with unexplained performance gaps and lost revenue.

Micro-Stop Detection, part of Orise’s Industrial AI Application, makes the invisible visible, capturing these hidden slowdowns in real-time and pinpointing their exact causes.

#what

What is Micro-Stop Detection?

Micro-Stop Detection is an AI-powered software solution that analyzes digital I/O signals from your production lines to identify and diagnose brief interruptions that conventional monitoring systems miss.

#how

How it Works

1

Connect to Existing PLCs

Direct integration with your current control systems

2

Collect and Process Signals

Real-time analysis of input and output data

3

Learn Normal Patterns

AI establishes baseline operations automatically

4

Report Deviations Instantly

Live alerts when micro-stops occur with precise root cause identification

Superior Ease of Use: No manual thresholds, new sensors, or PLC program changes required.

Each event is automatically timestamped and mapped to specific I/Os for precise traceability.

#benefit

The Benefits of Micro-Stop Detection

Pinpoint Root Cause without Manual Testing

Identifies the exact input or output responsible for each delay, eliminating guesswork during troubleshooting.

Identify Micro-Stops Before Output Decline

Captures sub-second interruptions in real-time and links them to root causes before production performance suffers.

Faster Diagnosis Through Direct Issue Mapping

Provides precise, timestamped I/O data instead of indirect symptoms or late-stage alarms.

Enhance Consistency with Existing Infrastructure

Improves machine performance without modifying logic or installing new sensors—uses only existing signal flow.

Enable Data-Driven Action

Empowers production and maintenance teams with targeted, data-backed insights rather than intuition-based decisions.

Quick and Easy Implementation

Delivers actionable insights without requiring data scientists, custom rules, or model development.

Product Features

High Frequency I/O Analysis

Continuously monitors digital inputs and outputs, detecting deviations within milliseconds of occurrence.

Root Cause Assignment

Pinpoints the specific sensor or actuator responsible for each detected interruption, cycle by cycle.

Model Management

Central interface to manage, train, version, and deploy monitoring models across asset types.

Customizable Alert Center

Delivers precise notifications via email, UI, or API, configured by machine, user role, or severity level.

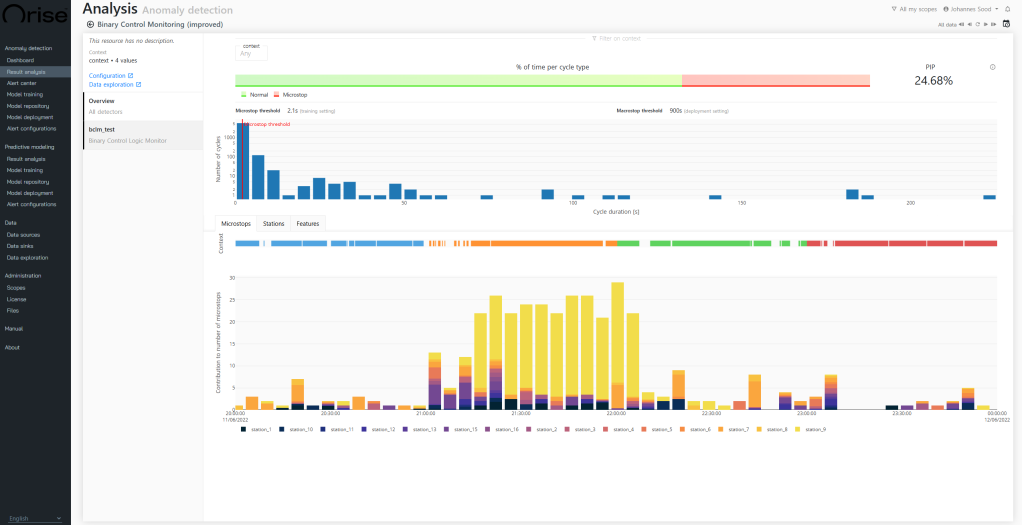

Live Analysis Dashboard

Provides real-time overview of alerts, machine trends, and anomaly history for investigation and tracking.

Multi-User Access

Enables structured collaboration for operations, maintenance, and management teams across sites.

Addressing Real Business Challenges

Unlike traditional performance monitoring that only tracks overall equipment effectiveness, or conventional AI that requires extensive data history and additional sensors, Micro-Stop Detection:

- Works proactively with minimal historical data requirements

- Identifies exact I/O causes behind delays

- Supports high-speed production cycles optimized for sub-second detection

- Scales easily across lines and teams

- Requires no additional hardware or data science expertise

#compare

Orise Industrial AI Application vs. Traditional Solutions

Traditional Performance Monitoring

Cannot detect short-cycle micro-stops or identify exact I/O causes

Conventional AI Systems

Require large data histories and often need additional sensors

Orise Micro-Stop Detection

Detects micro-stops in real-time, identifies exact causes, works with existing infrastructure

#case

Micro-Stop Detection in Action: Purmo Group

Challenge: Steam production at a waste incinerator plant was unstable due to significant variations in waste caloric value. The steam export required strict control over flow, pressure, and temperature.

Solution: Micro-Stop Detection analyzed digital I/O signals in real-time to automatically identify the main causes of short stops and slowdowns, enabling operators to see performance losses and act immediately.

Results:

- OEE increased from 67% to 85% within three months

- Full project cost recovery in less than six months

- Troubleshooting time reduced from hours to fewer than 60 seconds

- Improved availability, quality, and performance through data-driven operations

Frequently Asked Questions

How quickly can Micro-Stop Detection be implemented?

Implementation typically takes just a few weeks from connection to full deployment. The system works with your existing PLCs and requires no additional hardware or sensors.

What industries benefit most from this technology?

Pharma, biotech, chemical, energy, food, and beverage manufacturing operations with high-speed, automated production lines see the greatest impact, but any manufacturing organization will see benefits.

Do we need data scientists to operate the system?

No. The solution is designed for in-house teams and requires no data science expertise, custom rules, or manual model development.

Will this interfere with our existing production systems?

Micro-Stop Detection operates as a non-intrusive monitoring layer that reads existing I/O signals without modifying PLC programs or production logic.

How does it handle false alarms?

The AI continuously learns normal operational patterns and can be retrained with new data to reflect improved stability and changing operating conditions, minimizing false positives.

Start Detecting Hidden Production Losses Today

Transform invisible micro-stops into actionable insights. Contact Orise to implement Micro-Stop Detection and recover lost throughput across your production lines.