Supervisory Machine Control

What if an automated system could optimize your machine or process settings?

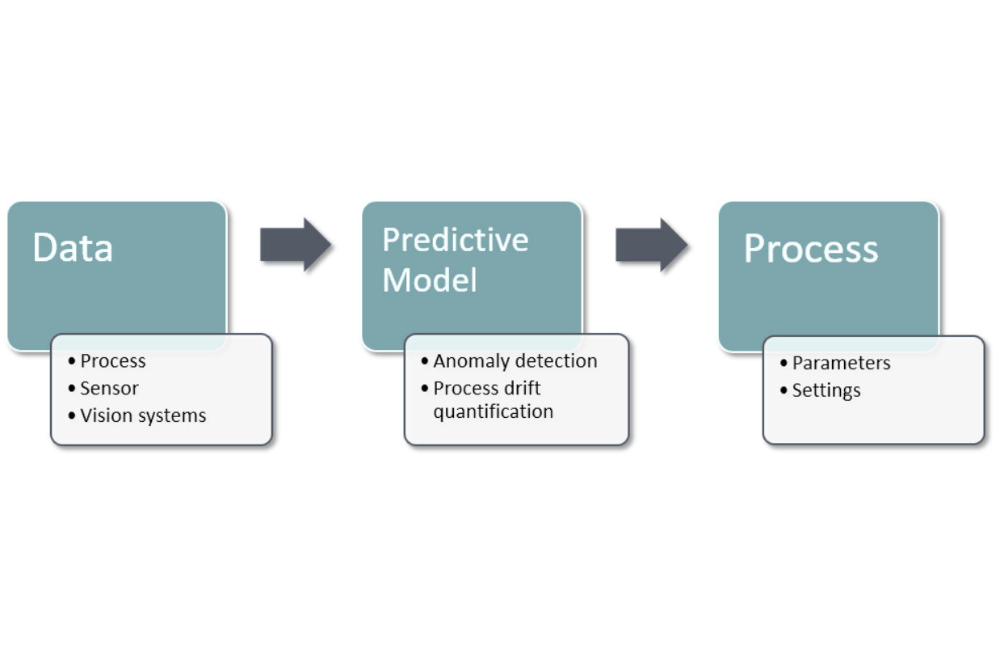

Design of Automated Supervisory Control & Advanced Process Control Based on Machine Vision or Sensor Data for Real-Time Production Parameters Tuning

Adjusting the settings of your machine or production process by means of human intervention is perfectly suitable if such adjustments are needed only infrequently, and if the need to make adjustments can be easily and quickly detected. However, that is not always the case.

For example, standard machine vision applications are used to check quality or presence and generate an alarm or send a signal to an actuator when a problem is detected. Changes to the process parameters to avoid bad quality or defects are usually done offline, manually.

This leads to long periods of sub-optimal production quality. The detection of problems occurs only after they cross the threshold set into the computer system.

Drive Digitalization Fast: Start Smart, Scale Fast

By combining our expertise in computer vision, machine learning, and advanced process control, we can derive process parameters from industrial camera images and other sensor data. Predictive models and AI algorithms detect anomalies or process drift in real-time, allowing smart software to adjust process parameters to prevent or minimize issues and/or damage.

This results in automated tuning of process parameters for real-time supervisory control, optimizing product quality, operational efficiency, productivity, and reducing downtime.

With our Computer Vision solutions you are accelerating your digitalization:

- While others require a strategic decision and lock you in, we keep you independent. And you remain the owner of both your data and the solution.

- While others can only add slow and are limited to step-by-step, we know how to master OT, multiply and scale fast.

Reference Projects:

- Real-time adjustment of pressure and temperature set points of refiners using color and thermal images, combined with a supervisory control algorithm to maximize production volume and quality. Customer under NDA.

- Real-time adjustment of steam flow set points of gas turbines and backup boilers based on steam flow demand, pressure controls, and a predictive model of electricity prices. Implemented with Umicore (non-ferro metals) in Belgium and a non-disclosed customer in the Netherlands.

- Real-time adjustment of tunnel oven setpoints to bake cookies with the desired brown color for customer La Confiance